Can Architects Save The World?

It is safe to say the most important steps toward achieving a sustainable building project within established cost constraints are performed during the project’s feasibility and design stages. The construction industry, by its very nature, is a big user of natural resources. But with growing concerns over climate change and the finite nature of these resources, there is increasing pressure on construction firms to reduce their environmental impact.

Greener practices from all businesses are now top concerns for consumers. They want to ensure that they’re leaving the smallest environmental footprint possible. Contractors and construction companies have picked up on this interest as more and more are now offering ‘green building’ in their construction.

According to the U.S. Census Bureau, construction spending in 2019 topped $1.3 trillion. During the first seven months of this year – 2020, construction spending amounted to $792.6 billion, 4.0 percent (±1.2 percent) above the $761.9 billion for the same period in 2019.

Industry at this scale comes with incredible costs. The construction industry has a massive impact on the environment because energy use is high. Building requires heavy machinery which relies heavily on fossil fuels, and sometimes inefficient electricity can result in the burning of fossil fuels further down the energy supply line. The construction industry accounts for approximately 36% of worldwide energy usage and 40% of C02 emissions.

Earth’s resources are not unlimited

Especially with the growth of the population, the need for sustainable construction becomes more pronounced. Sustainable building materials are essential for creating greener buildings—and a healthier world. Construction and demolition waste makes up about 40% of the total solid waste stream in the U.S. and about 25% of the total waste stream in the European Union, according to the United States Green Building Council (USGBC).

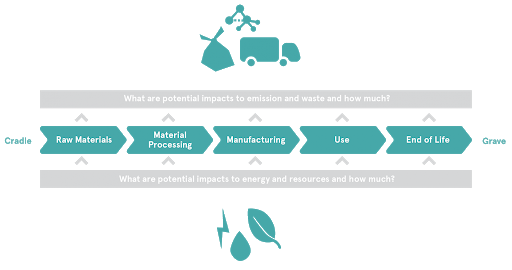

One has to look at the big picture when considering the impact of a building—the building’s life cycle. The American Institute of Architects’ Guide to Building Life Cycle Assessment in Practice discusses how to evaluate the potential environmental impacts for every stage of a building’s life. One important factor in the building’s life cycle is selecting sustainable building materials. Architects need to consider how building materials are sourced, manufactured, transported, used, and discarded during construction. Every detail matters.

Modern Sustainable Technology

The role of sustainable infrastructure not only benefits the planet but also the investor’s profit margin too. The primary financial goal of businesses is to make a profit. That being said, investing in sustainable technologies is a great start to creating profit. Builders who invest in modern sustainable technology can recoup those costs over time, which results in reduced building operational costs.

The industry standard for sustainable construction, LEED promotes codes and standards for construction firms to follow during the construction process. LEED is not an immediate action; it is functional for today, and in the future. Construction firms need to recognize that sustainable construction is increasing in demand worldwide.

The construction industry isn’t really set up for sustainability. Many of the resources used in one building are hard or impossible to reuse in another, actual construction can reduce air quality, and with the growing population there is a greater need for buildings. So, how does construction become sustainable?

Béton Du Chanvre

Starting in the early 1980s, French builders resurrected a form of building material known as béton du chanvre — now called hempcrete— which dates to circa 500 A.D. The process is simple: a mixture of crushed hemp hurd (material inside the stalk), water and lime. While often seen as a low-tech building solution, the technology has progressed in recent years to include pre-fabricated bricks and panels that have been employed in residential and commercial buildings across Europe and Canada.

The innovativeness of hemp concrete as a building material lies in its function as a multi-performance material. It can entirely replace mineral aggregates in conventional concrete, and historically it was added to concrete and mortars to avoid retractions in plaster or clay brick. When cured, it retains a large amount of air, with a density equivalent to 15% of traditional concrete, making it an excellent thermal and acoustic insulator. An interesting feature of the material is that it is both a good thermal insulator and has high thermal inertia. That is, though light and porous, hempcrete can quickly store energy and release it gradually, making it effective for climates with high temperature variation between day and night. It also has good fire resistance, is non-toxic, and is naturally resistant to mold and insects. There are even surveys that point to hempcrete being a carbon-negative material, which in addition to compensating for the carbon emitted in production, actually stores additional carbon within the material itself.

Nowadays, although there are legal barriers in many countries, the use of hemp as a construction material has had encouraging results, with research demonstrating its strong thermoacoustic and sustainable qualities. Hemp can be shaped into fibrous panels, coverings, sheets, and even bricks.

Cross-Laminated Timber

Another choice is mass timber. It is a category of construction characterized by the use of large solid wood panels for floors, walls and ceilings. Of particular focus in the mass timber family is Cross-Laminated Timber. CLT is kiln-dried lumber aligned in multiple layers, each at a right angle to the preceding layer and glued together under significant pressure. The result is a structural panel with exceptional biaxial strength, rigidity and stability.

As the term “mass timber” implies, CLT segments can be large; up to one foot thick and 10 feet by 40 feet or larger in width and length. Panels can be manufactured to custom sizes, which reduces on-site cutting to speed on-site construction. CLT’s strength makes it a viable option for floors, walls and roofs, and its natural aesthetics enable it to be used fully exposed. Developed in Germany in the early 1990s CLT soon became popular in Europe and is now gaining traction in the U.S. In 2015, CLT was incorporated into the American Wood Council’s National Design Specifications and into the International Building Code (IBC), which is the default code adopted by jurisdictions across the U.S.

The alternating fibers and solid composition of CLT give it the potential to substantially reduce the carbon footprint of new buildings by replacing structural concrete. It’s lightweight, strong, and fire and earthquake resistant.

Dalston Works—the world’s largest building constructed out of CLT—weighs approximately one-fifth of a concrete building of the same size. And on top of that, it was completed an estimated eight months faster than if traditional building materials had been used.

According to a study published by the Journal of Cleaner Production, timber is sourced from sustainably managed forests to maintain wood resources. One of the most important environmental benefits of using CLT is its carbon sequestration properties that aid in climate change mitigation. It is estimated that roughly one cubic meter of wood stores around 1.10 tonnes of carbon dioxide.

Here are some other examples of green building materials that you can use:

1. Solar Tiles

Regular roof shingles exist to protect your home from the elements, but don’t do anything with any of the energy they absorb. Solar tiles do both: they protect your home while converting solar energy into power for your home.

2. Sustainable Concrete

Concrete is responsible for 7-10% of global CO2 emissions. Sustainable concrete can include recycled materials that would otherwise have gone to waste. Similarly, grasscrete involves laying concrete with space for plant life, which reduces the material need as well as improving stormwater absorption and drainage capabilities. Hempcrete is another sustainable concrete alternative; it is a concrete-like material made with hemp fibers.

3. Bamboo

Bamboo may be lightweight, but when it comes to durability, it’s actually a strong replacement for many heavier materials. It’s fast-growing, which makes it a great renewable resource that’s environmentally friendly.

4. Wood

You can’t go wrong with wood: it’s been a reliable building material for centuries! When people properly manage forest and wood production, they provide a sustainable renewable material that is less energy-intensive to process other building materials.

5. Mycelium

Mycelium combines biology, design, and computing to create a unique building material composed of mushroom bricks. This material is strong, durable, and water-resistant.

Sustainable Interior Finishes

Although the bulk of the energy-saving work is done in the building envelope, interior finishes can also play a role in indoor environmental quality, carbon sequestration, and communicating sustainability to occupants and other stakeholders. The number of green design materials available has exploded in recent years. Products that used to be offered in limited colors or designs are now as varied as their traditional counterparts. Because of consumer demand, sustainable painting, flooring, and countertop products that might have been less durable and expensive in the past are now stronger, longer-lasting, and often more affordable.

Paint: Nearly every major paint company has created its own green line, but not all green paints are created equal. A new generation of low-VOC or zero-VOC (Volatile Organic Compounds) paints give homeowners a healthier option. The new range of paints is every bit as durable as their unhealthier predecessors, but with a plethora of health and environmental benefits. The water-based paints are easier to clean and release fewer landfill, groundwater and ozone depleting contaminants. The paints are a far better choice for everyone, especially those with respiratory ailments, allergies or chemical sensitivities.

Sealants / Adhesives: The risk with most finish materials is that chemical adhesives used during installation can counteract the healthy qualities of products that have been manufactured to be green. Sustainable adhesives and sealants contain little to no solvents meaning that less or no VOC are released during the application and curing, nor in the finished product.

Flooring: Wood is one of the best earth-friendly and renewable materials you can choose. Not only are fewer raw materials used in creating them, but they also require less energy and natural resources. While materials like bamboo and cork are popular types of sustainable wood flooring, they can be limited in their durability – especially when compared to hardwood floors. Cork is a softer wood, harvested from the bark of oak trees, whereas bamboo floors actually come from the grass family.

Countertops: The most common kitchen counters you will find in homes are traditional laminate countertops. And they certainly live up to the adage ‘you get what you pay for’, as most of them still contain a lot of formaldehyde and they aren’t very durable. IceStone is one of the most popular recycled countertops out there with a spectrum of colors available. Another is PaperStone is made of 100 percent post consumer paper fused with a petroleum-free resin derived from cashew liquids.The material more closely resembles wood than stone, making it much easier to work with.

Sustainable Textile

As the demand for eco-design and sustainable furniture has increased, the textile industry has adapted to this trend. In modern textile production, therefore, the use of polluting chemicals is dispensed with. In addition, attention is paid to the environmentally friendly extraction of raw materials. Here are some examples:

Hemp Fiber: considered by many as the most versatile and sustainable plant on earth. Its skin is tough and insect resistant, and this is why often hemp is used as a rotation crop. Its fiber and oil can be used in making clothes, papers, building material, food, skin care products and even biofuels.

Organic Linen Fiber: Linen fabrics are made with flax fibers. You can find flax fiber’s excellent properties in the hemp fiber info section.While growing flax is far more sustainable and causes less pollution than conventional cotton, herbicides have been commonly used in conventional cultivation as flax is not very competitive with weeds.

Organic cotton: is an ecologically responsible and green fiber. Unlike conventional cotton, which uses more chemicals than any other crop, it is never genetically modified and does not use any highly polluting agro-chemicals such as those found in pesticides, herbicides and many fertilizers. Integrated soil and pest management techniques—such as crop rotation and introducing natural predators of cotton pests—are practiced in organic cotton cultivation.

Natural wool: is obtained by the annual shearing of sheepskin. Pure new wool expresses that it comes from a living animal. Organic wool also comes from animal welfare. The quality of the wool depends on the body regions, age and origin of the animal.

Bamboo: is a rapidly growing grass plant. It can be harvested every 2-3 years without having to re-plant it. It uses less water for cultivation, no pesticides and improves soil quality. Fabric from bamboo is moisture absorbent, hypo-allergenic and anti-bacterial. Bamboo fabric is very soft to touch and is made use of in luxurious upholstery.

Kapok Fiber: comes from the Kapok tree and is 100% natural. The first and most important to notice is probably that kapok is wild grown and therefore it does not need any artificial watering! Kapok trees are native to Mexico, Central America and the Caribbean. The “tree wool”, as kapok is called as well, grows in big pods on the trees and the ripe unopened pods are normally harvested by knocking them off the tree. Afterwards, the fruits are hulled and seed and fibre are removed from the pods by hand. A tree yields about 15 kg of fiber a year. For 1 kg of kapok you actually need 15 pods

TENCEL™ Lyocell fiber

Another product leading sustainability in the textile industry is TENCEL™ Lyocell fiber. The fibers originate from the renewable raw material wood, created by photosynthesis. The certified biobased fibers are manufactured using an environmentally responsible production process. The fibers are certified as compostable and biodegradable, and thus can fully revert back to nature. TENCEL™ Lyocell fiber have gained a commendable reputation for their environmentally responsible closed loop production process, which transforms wood pulp into cellulosic fibers with high resource efficiency and low environmental impact. They are found in the collections of many leading designers and renowned retailers because they answer both the demand for sustainability and style.

Final Thoughts

The construction industry is undeniably making a profound impact on the environment; thus, it becomes extremely important that companies work towards maximizing the positive benefits while minimizing its negative component. Sustainable buildings are designed to help reduce the overall impact on the environment and human health during and after construction.

Aside from a lower impact on the environment, green buildings also create healthier, more comfortable indoor environments for the people who use them. Protecting the planet and promoting the physical well-being of the occupants are equally significant. This is beyond important for the future of our society.

Our future and our children’s future depend on our efforts to be more green and our ability to use sustainable materials.

Would you like to learn more about how you can jumpstart your way into creating a greener home for your family?

Call 1-866.815.0099

and tell us more about your project.